Application

Are large-sized PP parts prone to deformation and lack of luster?

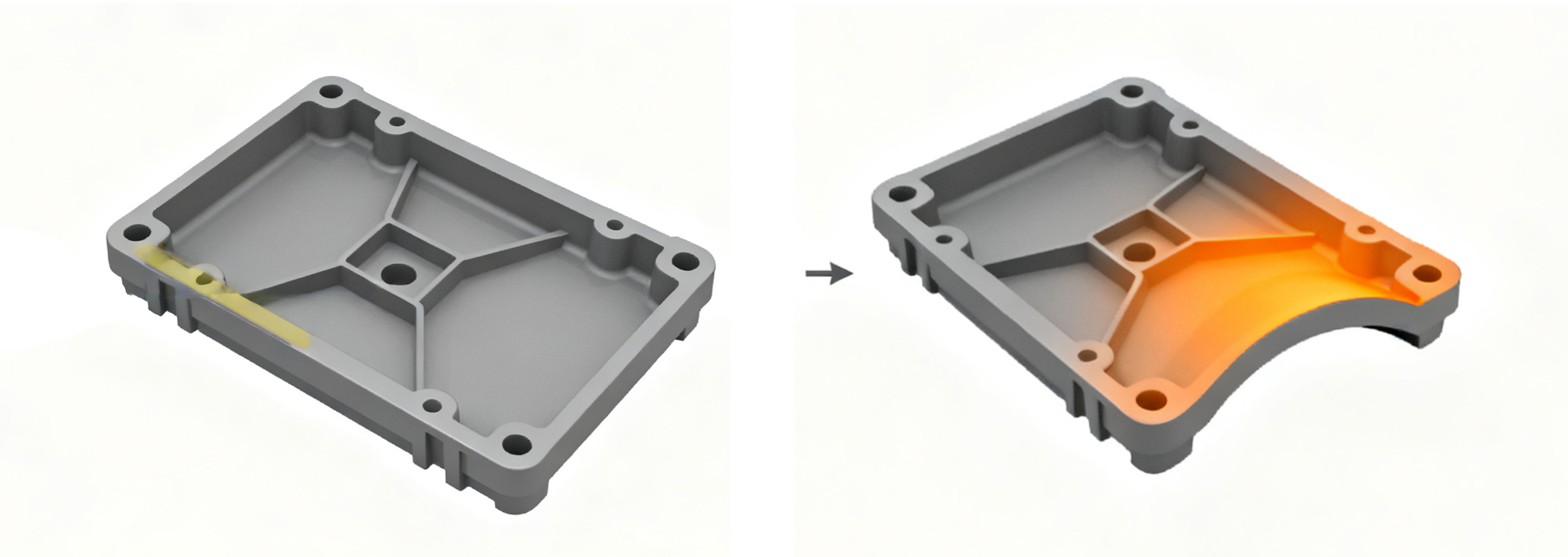

In production, large PP parts (such as home appliance casings, furniture components, automotive interiors, etc.) are prone to deformation problems such as warping and shrinkage. Especially when the products require both high surface gloss and high-temperature resistance, many traditional modification methods often find it difficult to achieve both. What are the materials science roots behind this common technical problem? Then how can it be solved efficiently and at a low cost?

I. Why are large-sized PP parts prone to deformation?

Polypropylene (PP), as a semi-crystalline polymer, has a relatively high shrinkage rate (typically reaching 1.5%-1.8%), which can easily lead to uneven shrinkage during the injection molding process of large parts, thereby causing warping and deformation. This problem is even more prominent in products with complex structures and significant differences in wall thickness.

On the other hand, if one hopes to enhance rigidity and heat resistance through filling modification, conventional fillers (such as calcium carbonate, talcum powder, etc.) can improve dimensional stability to a certain extent, but they often sacrifice surface gloss and even lead to appearance defects such as whitening and floating fibers on the surface.

Ii. How to achieve high gloss, high temperature resistance and low deformation simultaneously?

To achieve a balance among multiple performances, the key lies in choosing a filling system that can be multi-functionally and synergistically modified - and barium sulfate is precisely the functional filler that performs exceptionally well in this scenario:

Barium sulfate - A powerful tool for enhancing high gloss and heat resistance

Enhance surface gloss: Barium sulfate has excellent dispersibility and refractive index matching. After filling, the products can still maintain an outstanding surface bright effect, even better than unfilled PP.

Good heat resistance: It helps maintain the morphological stability of the material in a high-temperature environment and slows down thermal deformation.

Reduce overall shrinkage rate: Although the effect of improving shrinkage alone is not as obvious as that of talcum powder, when combined with other synergistic fillers, it can comprehensively enhance dimensional stability.

Recommended combination plan: Barium sulfate + talcum powder

We suggest adopting the modified route of using barium sulfate in combination with talcum powder,Barium sulfate as the main component - ensuring high gloss and surface texture; Talcum powder as an auxiliary - significantly enhances rigidity and dimensional stability, and inhibits shrinkage deformation; Adjust the appropriate proportion - to achieve the optimal performance configuration without significantly increasing costs. Typical application scenarios

This solution is particularly suitable for large-sized injection molded parts that have high requirements for both appearance and size, such as:

Small household appliance shells: air purifier panels, dishwasher panels; Furniture components: Seat shells, storage boxes; Commercial equipment: water dispenser shells, instrument panels.

By choosing barium sulfate as the main functional filler and combining it with talcum powder and other materials for compound modification, multiple performance aspects can be improved in a coordinated way at a relatively low cost - truly achieving "both luster and stability".

We are committed to the development and application of barium sulfate-based modified materials. We can provide free samples for customers. Welcome to contact us!