Application

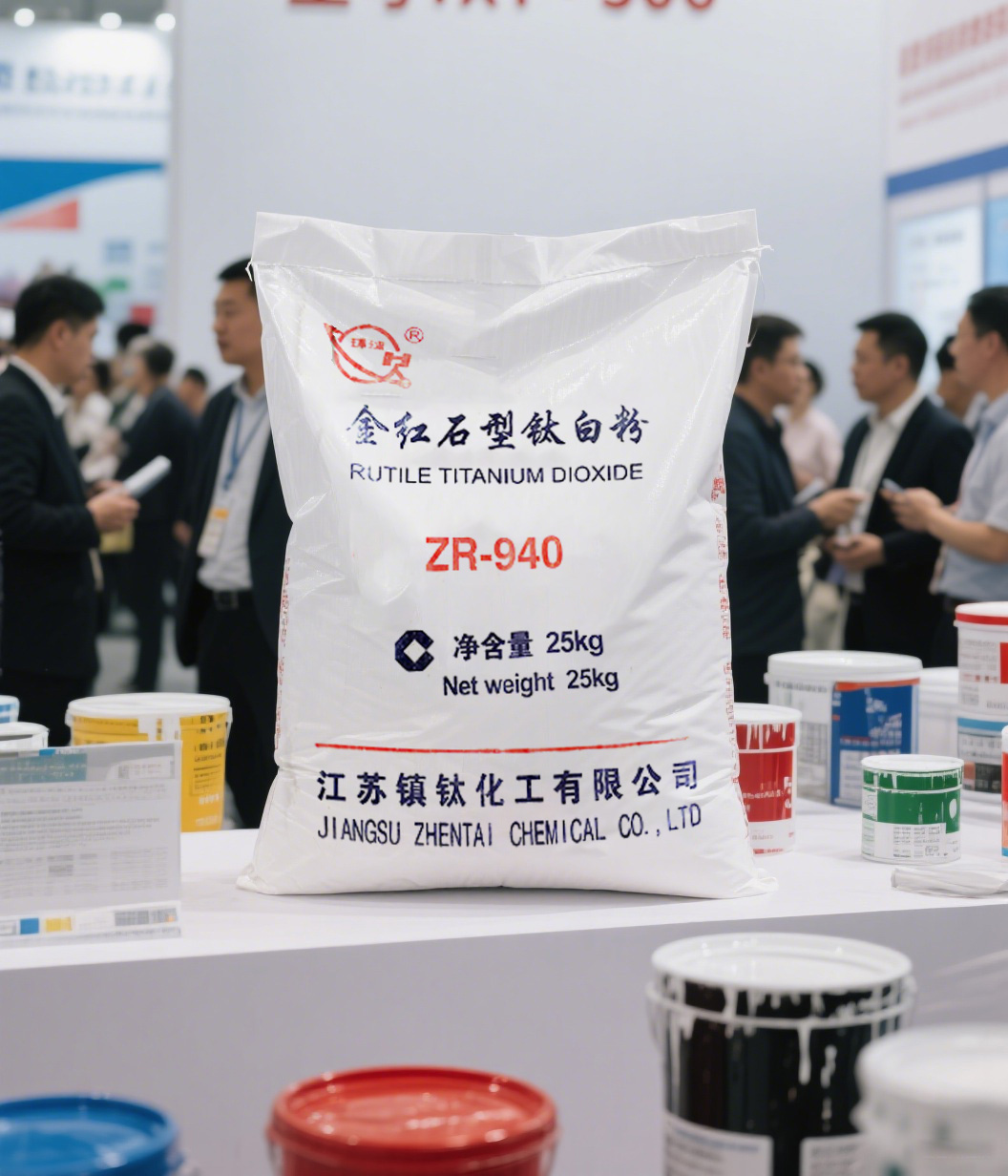

ZR-940 Titanium Dioxide is produced via the sulfate process with SiO2 and Al2O3 treatment,delivering stable hue, superior opacity, and excellent dispersion.

Color difference problem? The inconsistent colors of the batches affect the appearance of the products?Insufficient coverage? Is it necessary to apply it thickly or in multiple coats? Poor weather resistance? Is it prone to yellowing and powdering outdoors? Next, we will provide you with a detailed introduction to ZR-940 titanium dioxide and how it addresses the core pain points of the industry!

| Project | Detailed description |

| Product model |

ZR-940 |

| Production process | Sulfuric acid process |

| Crystal form structure |

Rutile type |

| Surface treatment |

Silicon-aluminum composite coating |

| Product features |

Excellent hue stability High covering power Good dispersibility Stable yellowish phase |

Solutions to industry pain points

01 Application of Powder Coatings

Industry pain points:

-

Titanium dioxide has insufficient heat resistance and is prone to yellowing during high-temperature curing.

-

It has poor covering power and requires multiple sprays to achieve the desired effect, which increases the cost.

ZR-940 Solution

✅ rutile type structure - excellent high-temperature resistance, reducing the risk of yellowing during baking.

✅ High covering power - high covering power can be achieved with a single layer of spraying, reducing the amount of paint used and improving production efficiency.

✅ Good compatibility - high compatibility with the resin system, reducing surface defects of the coating (such as pinholes, orange peel).

02 Application of printing color paste

Industry pain points:

-

Ordinary titanium dioxide is prone to hue drift, resulting in inconsistent colors between batches of printed fabrics.

-

Poor dispersibility affects the stability of the slurry and is prone to sedimentation or caking.

ZR-940 Solution

✅ silicon-aluminum coating technology - enhances hue stability, reduces batch color difference, and ensures color consistency in printing.

✅ Excellent dispersibility - reduces grinding energy consumption, improves slurry uniformity, and avoids screen clogging.

✅ High covering power - reduce titanium dioxide usage, lower costs, and ensure bright printing effects at the same time.

Summary: Why choose ZR-940?

✔ Stable color phase - Silicon-aluminum coating technology reduces batch differences and is suitable for high-demand color applications.

✔ High covering power - Reduce usage, lower costs, and enhance the quality of coated/plastic products.

✔ Strong weather resistance - suitable for outdoor coatings and plastic profiles, resistant to UV and yellowing.

✔ Good dispersibility - reduces processing energy consumption, improves production efficiency, and avoids problems such as caking and sedimentation.

With its stable quality and excellent performance, ZR-940 has become an ideal choice for industries such as printing pastes, coatings, inks, and plastics, helping customers enhance the competitiveness of their products!

Product technical parameters (Reference)

| Project | Detailed description |

| Tio2 content % |

≥92 |

|

Rutile content % |

≥98 |

| Oil absorption capacity: g/100g |

≤23 |

| 45μm sieve residue % |

≤0.05 |

| 105℃ volatile % |

≤1.5 |

Xintu Chemical: Your reliable coating filler and solution partner